In today's industrial landscape, the efficiency and longevity of equipment are critical for ensuring optimal operations, especially when it comes to Diaphragm Pumps. According to a report by the Hydraulic Institute, properly maintained pumps can lead to a 20% reduction in operational costs, significantly impacting a company's bottom line. Furthermore, the International Pump Users Group highlights that inefficient pumping systems can waste up to 30% of energy, underlining the importance of optimization strategies. By implementing best practices in diaphragm pump management, such as regular maintenance, the right material selection, and precise calibration, businesses can enhance their pumps' performance, prolong their lifespan, and reduce their environmental footprint. This guide will provide practical insights into maximizing the efficiency of diaphragm pumps, significantly contributing to sustainable operations and cost savings.

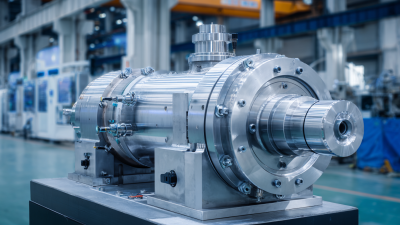

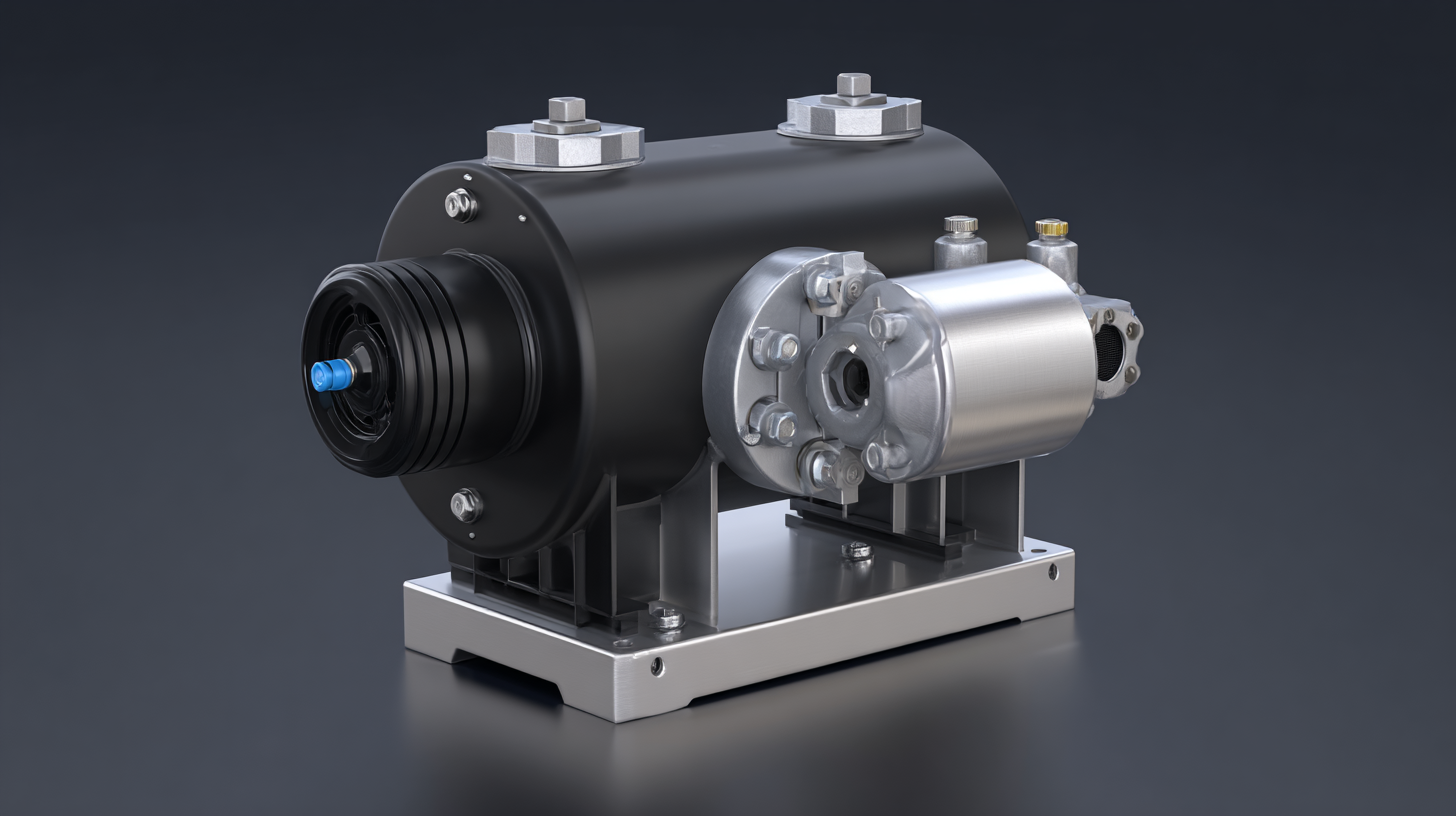

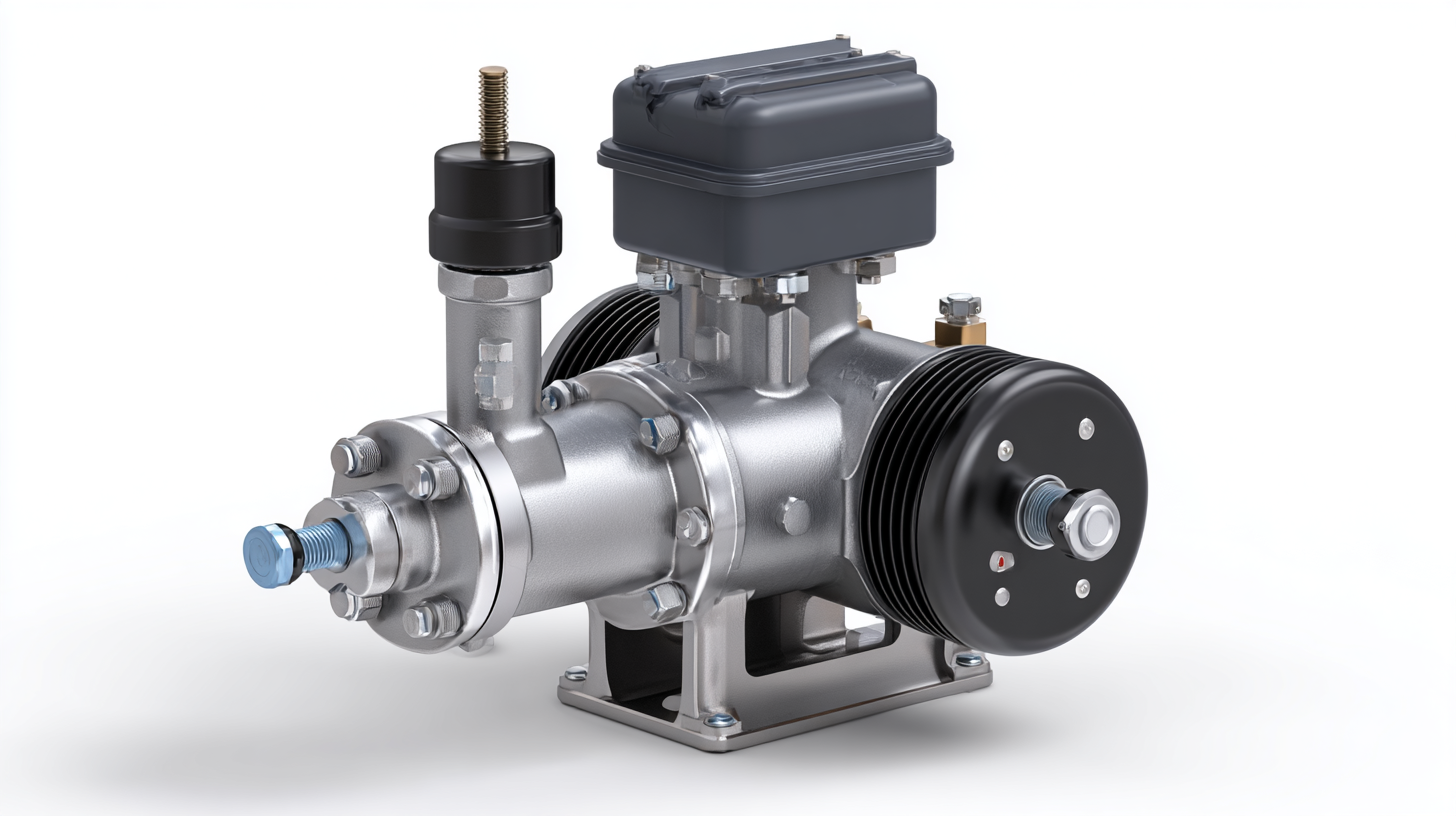

Diaphragm pumps are essential tools in various industries, providing a reliable means to move fluids. Their efficiency and longevity can be significantly improved through a basic understanding of their operational principles. These pumps utilize a flexible diaphragm to create a vacuum and draw in the fluid, making them ideal for applications requiring precision and control. Besides their mechanical functioning, attention to system dynamics, such as pressure and flow rates, can enhance performance. Recent advancements show that some diaphragm models minimize compressed air usage, which allows for energy-efficient operations and reduced costs.

**Tips:** When optimizing your diaphragm pump, ensure that the air supply is regulated to prevent excessive consumption. Regular maintenance, including checking seals and diaphragms, is crucial for maintaining efficiency. Moreover, selecting materials that withstand corrosive environments can further enhance the pump's longevity, especially in demanding applications, thereby minimizing downtime and maintenance costs. Implementing these strategies will not only boost the operational efficiency of your diaphragm pump but also extend its life span in the field.

| Parameter | Optimal Value | Impact on Efficiency | Recommended Maintenance Frequency |

|---|---|---|---|

| Air Supply Pressure | 80-100 psi | High pressure ensures optimal flow rate | Every 6 months |

| Diaphragm Material | PTFE or Nitrile | Durable materials extend pump life | Every 1 year |

| Seal Condition | No visible wear | Maintaining seals prevents leaks | Monthly check |

| Pumping Speed | Adjust as needed | Proper speed maximizes throughput | Every use |

| Temperature of Fluid | Room temperature | Maintains viscosity for optimal flow | Every month |

To enhance the performance and longevity of your diaphragm pump, regular maintenance practices are essential. Implementing a structured maintenance schedule can help identify potential issues before they escalate into costly repair needs. Regular inspections of the pump's components, including valves and diaphragms, can ensure that any wear and tear are addressed in a timely manner.

Tips: Frequently check for leaks and unusual noises during operation, as these can indicate underlying problems. Clean the pump regularly to prevent buildup of debris that can affect performance. Additionally, replacing worn diaphragms and valves promptly can significantly prolong the service life of your pump.

Another important aspect of maintenance is ensuring the correct operating conditions. Monitoring the fluid being pumped and its compatibility with pump materials can prevent chemical damage. Maintaining appropriate pressure levels and avoiding overloading the pump are also critical to avoiding premature failure.

Tips: Keep a log of maintenance activities and operational changes to help track performance trends over time. Educate your team on best practices for pump operation and maintenance, as proper handling can greatly reduce wear and tear.

When optimizing diaphragm pumps, identifying and troubleshooting common issues is crucial for achieving maximum efficiency and longevity. One frequent problem is inconsistent flow rates, which can often be attributed to blockages in the inlet or outlet. Regular inspection of these pathways is essential; any buildup of debris or sediment can disrupt the pump's performance. Additionally, monitoring the condition of the diaphragm itself is critical, as wear and tear can lead to leaks and reduced efficiency. Ensuring that the materials used in the diaphragm are suitable for the pumped fluid can also help prevent early degradation.

Another common issue is air entrapment, which can lead to erratic pump operation and diminished performance. To tackle this, operators should ensure that the pump is properly primed and check for any leaks that may allow air to enter the system. Utilizing bleed valves can help release trapped air, allowing for smoother operation. Furthermore, regular maintenance checks should include examining the seals and gaskets for wear, as failing to address these components can result in significant efficiency losses over time. By proactively addressing these common issues, operators can enhance the reliability and lifespan of their diaphragm pumps.

When optimizing your diaphragm pump for maximum efficiency and longevity, selecting the right materials and components is crucial. The materials used for the diaphragm itself should have excellent resistance to the chemicals being pumped, as well as durability to withstand repetitive flexing. Common choices include PTFE and various elastomers that offer chemical compatibility and longevity. Additionally, the choice of components such as valves and seals can significantly influence performance. Using high-quality, wear-resistant materials can reduce maintenance needs and extend the pump's operational life.

Furthermore, consider the design and compatibility of the pump components. For instance, ensure that the pump's dimensions align with the specific application requirements. Proper sizing prevents issues such as cavitation, which can lead to premature wear. Additionally, using components from reputable manufacturers can guarantee consistent performance and reliability. Investing time in selecting the right materials and components not only optimizes efficiency but also minimizes downtime, ensuring the diaphragm pump operates at peak performance for years to come.

Leveraging technology in diaphragm pump operations

is a game-changer for achieving peak performance. Modern monitoring systems equipped with sensors can provide real-time data on various operating parameters such as

pressure,

flow rate, and

temperature. This data empowers operators to identify any deviations from normal operating conditions swiftly, allowing for timely interventions that can prevent costly downtime and repairs.

Furthermore, integrating predictive maintenance technology can help forecast potential failures before they occur, extending the life of the pump significantly.

Automation plays a crucial role in optimizing diaphragm pump efficiency. Automated control systems allow for precise adjustments to pump speeds and pressures, adapting to varying operational demands seamlessly.

With smart automation, the pump can operate at its optimal capacity, reducing energy consumption and enhancing reliability. Additionally,

advanced algorithms can analyze historical performance data to fine-tune operations continuously, ensuring that the pump performs under ideal conditions. Adopting these technological advancements not only maximizes efficiency but also ensures sustained longevity of diaphragm pumps in various applications.